- Servo Gearbox Torque Calculator For Sale

- Servo Gearbox Torque Calculator Parts

- Servo Gearbox Torque Calculator Conversion

- Servo Gearbox Torque Calculator Online

Servo motor sizing spreadsheet allows to calculate a combination of motors and gearboxes that fits a user-defined working condition. The results can be sorted depending on various parameters (e.g. Speed, torque, safety ratio, etc.). Servo motor sizing spreadsheet can be tried for free for 15 days. If the control surface has a full sweep angle of 40 degrees. From Center or the neutral point, 20 degrees would be entered. The calculator only calculates one control surface per servo. If you are using one servo for two control surfaces, the calculated torque must be doubled. This in many cases is common for the aileron channel. Calculation for Required Torque ( TM ) The required torque is calculated by multiplying the sum of load torque and acceleration torque by the safety factor. Calculation for the Effective Load Torque ( Trms ) for Servo Motors and BX Series Brushless Motors. When the required torque for the motor varies over time, determine if the motor can be.

When designing machinery that uses lead screws, it's a common task to try and figure out the size of motor needed to drive a given force with a lead screw. This calculator will calculate torque given the lead screw parameters and the required force.

There are two torques the torque to raise the load and the torque to lower the load.

Servo Gearbox Torque Calculator For Sale

Once the torque is calculated an appropriate stepper can be selected.

| Common Stepper Motor Typical Torque Ranges and Dimensions | |||

|---|---|---|---|

| Motor | Torque in N*cm | Dimensions | Shaft Diameter |

| NEMA 8 | 4 | 20mm sq | 4mm,5mm |

| NEMA 11 | 11-13 | 27mmx sq | 5mm |

| NEMA 14 | 9-15 | 35mmx sq | 5mm |

| NEMA 17 | 44-54 | 42mmx sq | 5mm |

| NEMA 23 | 180-300 | 57mmx sq | 0.25 in |

| NEMA 34 | 200-1100 | 86mmx sq | 14mm |

Coefficient of Friction for Leadscrew Threads

Servo Gearbox Torque Calculator Parts

| Screw Material | Nut material | |||

|---|---|---|---|---|

| Steel | Bronze | Brass | Cast iron | |

| Steel, dry | 0.15 - 0.25 | 0.15 - 0.23 | 0.15 - 0.19 | 0.15 - 0.25 |

| Steel, machine oil | 0.11 - 0.17 | 0.10 - 0.16 | 0.10 - 0.15 | 0.11 - 0.17 |

| Bronze | 0.08 - 0.12 | 0.04 - 0.06 | - | 0.06 - 0.09 |

Equations:

These equations come from the Wiki article on force.

Torque(raise) = F*Dm/2*(L+u*PI*DM)/(PI*Dm-u*L)

Torque(lower)= F*Dm/2*(L-u*PI*DM)/(PI*Dm+u*L)

Servo Gearbox Torque Calculator Conversion

Motor Shaft Conversion Torque: TO

Z1 : Teeth number of the motor-side gear

Z 2 : Teeth number of the load-side gear

R : Speed reduction ratio Z2/Z1

η : Transmission efficiency % /100

T : Load-side torque[N・m]

| To= | 1 | ・T・ | 1 | [N・m] |

| R | η |

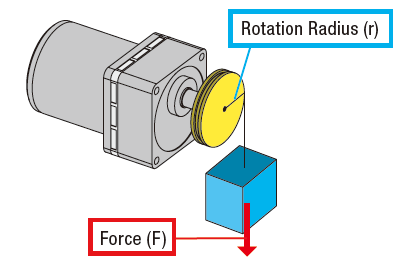

Torque when Adding the External Force of the Rotating Object: T

D : Diameter of the drum [m]

F : External force[N]

| T= | 1 | D・F [N・m] |

| 2 |

Torque by Friction Force of the Feed Screw and External Force: T

P : Feed screw lead[m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the feed screw

F : External force[N]

| T= | 1 | P(F+μMg) [N・m] |

| 2π |

Servo Gearbox Torque Calculator Online

(Normally, μ : approximately 0.05 to 0.2)

Torque by Friction Force of Rack and Pinion and External Force: T

D : Diameter of the pinion [m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the rack and pinion

F : External force[N]

| T= | 1 | D(F+μMg)[N・m] |

| 2 |

(Normally, μ : approximately 0.08 to 0.1)

Torque by Friction Force of Conveyor and External Force: T

D : Diameter of the roller [m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the conveyor

F : External force [N]

| T= | 1 | D(F+μMg)[N・m] |

| 2 |

(Normally, μ : approximately 0.05 to 0.1)

* The friction coefficient value μ varies depending on the machine processing accuracy, lubrication condition, and other factors.

Pay enough attention when calculating the load torque.

* The transmission efficiency η between the motor and load varies depending on the connection method. The following shows typical values.

Spur gear: 0.85 Chain: 0.9 V-belt: 0.9

Other Technical Documents